Hold Down Roller Eliminator

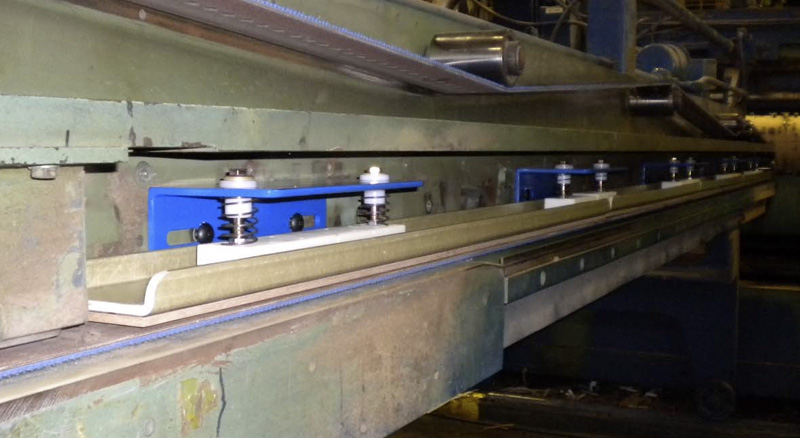

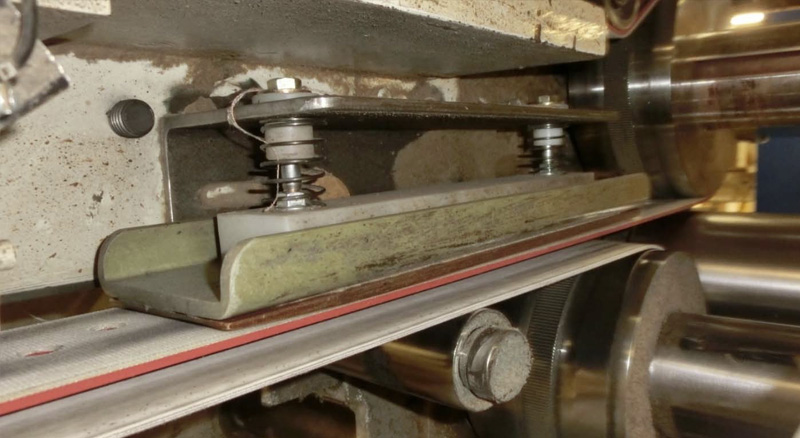

The JKS Roller Eliminator system completely eliminates the rollers in the folding section of the machine, replacing them with heavy‐duty, ultradurable, spring‐loaded boxes, that provide a uniform and smooth surface for the belts to ride on. There is NO maintenance required to maintain the integrity of the system, and no possibility of uneven belt transfer.

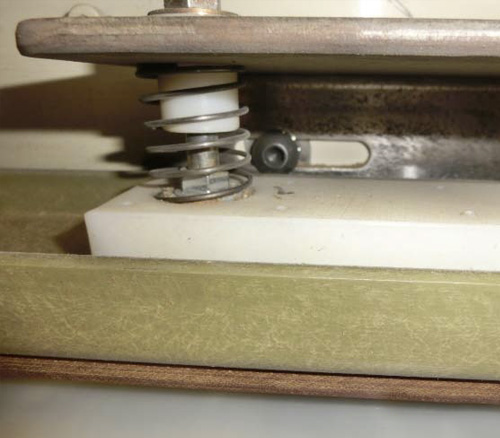

OEM Style Hold-Down Roller System

JK Services Roller Eliminator

Langston Saturn flexo folder‐gluers come stock with a series of rollers for the folding section transfer belts. Over time, the rollers collect dust and wear out, requiring replacement, and causing uneven belt transfer in the interim.

System Benefits Include

Productivity

- No operator intervention adjusting or manipulating hold-down rollers. (up to 30 minutes per 8 hours)

- Faster run speeds due to increased box squareness and reduced belt twisting. (up to 25% faster)

Quality

- Square boxes - provides a continuous nip, improves belt tracking, reduces belt twisting, and eliminates issues with operator and drive side belts running at different speeds.

- Improved gap variation consistency - reduced plowing, toeing, skewing, and fishtail.

Cost Savings

- Zero maintenance cost. No need to replace rollers, bearings, bushings, etc. (annual savings up to $10,000 USD)

- Compatible with standard rough-top belts. No need to purchase expensive offset suction cup vacuum belts. (two-year savings up to $10,000 USD)

Maintenance Effort

- Zero maintenance required. (saves up to 60 hours per year)

- Fewer jam-ups due to improved belt tracking. (up to 30 minutes per jam)

*A JK Services Product