Creaser Yoke Upgrade

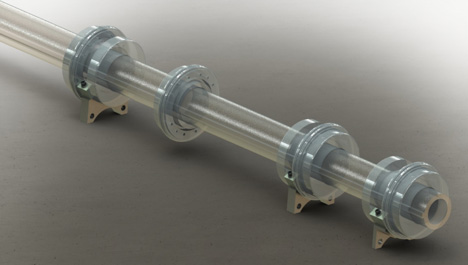

In addition to slotter head yokes, Sauer System provides creaser yokes that are specifically designed to enhance folding performance on the Saturn.

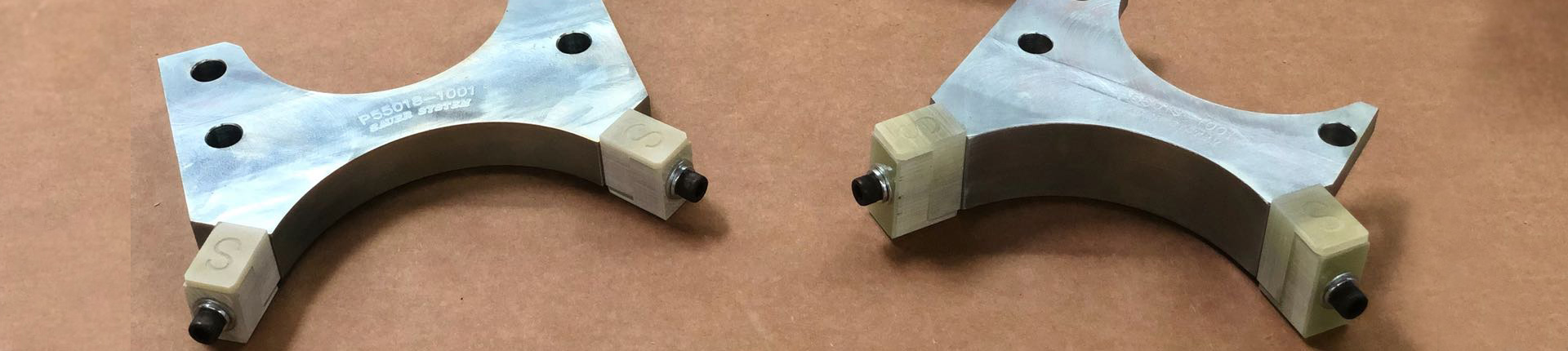

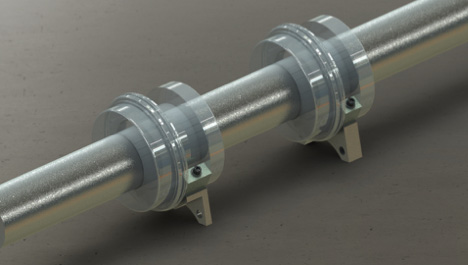

While many factors can cause folding issues, not maintaining male creaser head yokes can lead to issues where the scorers move laterally during machine operation, creating score lines that are off center. Sauer System creaser yokes help make maintaining alignment of creasers easy.

Sauer Shoe System designs yokes for the male creasing heads hold the creasing rings in the correct position (with the scoring bead centered in the slot), allowing for improved folding and gap variation consistency. The small diameter of the creasing heads coupled with fast run speeds quickly leads to lateral play. The creaser yoke upgrade allows for quick adjustments to remove the lateral play in a matter of seconds.

System Benefits Include

Productivity

- No operator intervention adjusting or manipulating hold-down rollers. (up to 30 minutes per 8 hours)

- Faster run speeds due to increased box squareness and reduced belt twisting. (up to 25% faster)

Quality

- Square boxes - provides a continuous nip, improves belt tracking, reduces belt twisting, and eliminates issues with operator and drive side belts running at different speeds.

- Improved gap variation consistency - reduced plowing, toeing, skewing, and fishtail.

Cost Savings

- Zero maintenance cost. No need to replace rollers, bearings, bushings, etc. (annual savings up to $10,000 USD)

- Compatible with standard rough-top belts. No need to purchase expensive offset suction cup vacuum belts. (two-year savings up to $10,000 USD)

Maintenance Effort

- Zero maintenance required. (saves up to 60 hours per year)

- Fewer jam-ups due to improved belt tracking. (up to 30 minutes per jam)