Sauer System now offers a yoking system that replaces the OEM style yokes that utilize a carbide button system. The carbide button yokes have created a challenge for many maintenance departments for the following reasons:

Sauer System now offers a yoking system that replaces the OEM style yokes that utilize a carbide button system. The carbide button yokes have created a challenge for many maintenance departments for the following reasons:

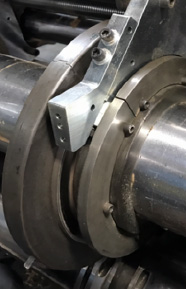

Sauer System has developed a yoking system where each yoke can be adjusted in a matter of seconds and where visual inspection is easy.

The new yokes utilize a spring-loaded composite block mechanism that allows for extremely quick and accurate adjustments.

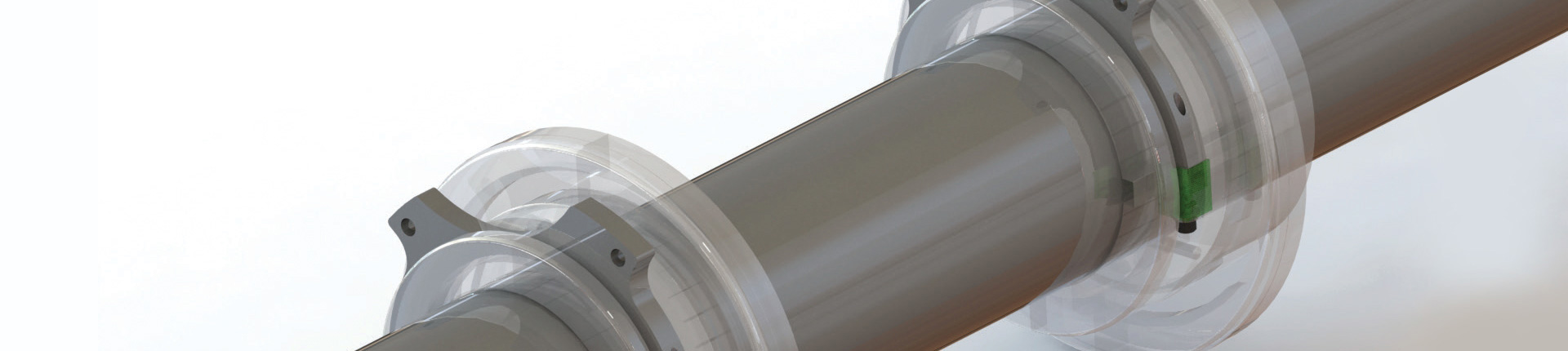

The cut-away diagram shows the internal springs. The wear blocks are held closed with an end bolt. When the composite block pieces wear down, loosening the end bolt allows for the pieces to spring out and compensate for the wear. Tightening the bolt holds the adjustment in place.

As an added benefit, the wear blocks have clearance such that they are self-aligning.